micro hammer for grinding dry samples

micro hammer for grinding dry samples: /5Micro Hammer For Grinding Dry Samples Micro Mill PULVERISETTE 0 is the ideal laboratory mill for fine comminutio

WhatsApp)

WhatsApp)

micro hammer for grinding dry samples: /5Micro Hammer For Grinding Dry Samples Micro Mill PULVERISETTE 0 is the ideal laboratory mill for fine comminutio

Dry granulation can be conducted on a tablet press using slugging tooling or on a roller compactor commonly referred to as a When a tablet press is used for dry granulation, the powders may not possess enough natural flow to feed the product uniformly into the die cavity.

#0183;#32;Dry granulation is a powder agglomeration process used in a variety of industries including pharmaceutical, mineral, and chemical industries. In the pharmaceutical industry, the dry granulation method, which is a continuum process well suited for active pharmaceutical ingredients that are sensitive to water and other solvents, is used to improve the flowability of powders by increasing the

mecanque diagram of a hammer mill granulation Jamaica. granulation hammer mill granulation hammer mill Granulation operation of water drop type feed hammer mill 1 The waterdrop type feed hammer mill should check the machine for any debris and tools before starting the machine If necessary open the valve to check whether the parts and the discharge screen are damaged 2 Get price .

Dry Granulation:The Definitive Guide Do you want to be an expert in dry granulation process? If yes, then this is the BEST guide for you. Reason: I am going to take you through an indepth analysis of critical aspects about dry granulation techniques. From the definition, basic principles, advantages, disadvantages, machines, practical applications to factors []

Lb Dry Grinding Micro Granulation. STM Machines For Dry Grinding And Selection Mills. STM is at the cutting edge of design and manufacture of machines for dry grinding and selection Our milling machines and dynamic classifiers can process many types of product into powder or grains Our dry grinding technologies give excellent performance in

WFJ super fine micro pulverizer. grinding machine. : : CH Jiangyin Kangwo Machine Co.,Ltd is a professional company specializing in the design and manufacture grinding machine,pulverizer,mixer,charging machine,dryer,etc Two common methods of granulation wet granulation and dry granulation. 23 201609. What

LB (1) LCI (10) LEOPARD IMPIANTI (1 screenless technology for the most efficient and cost effective grinding of glassfilled plastics Screenless technology allows for no longs Antiwear machine housing Ladder blade rotor configuration for films and hollow plastics Suitable for wet and dry granulation

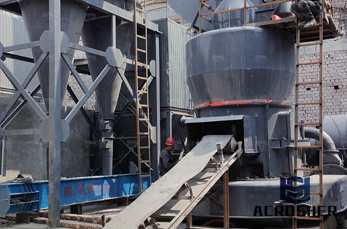

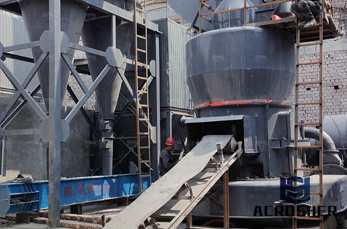

With an order shipped to recentlyformed ceramic tile manufacturer Lingshi, LB has begun 2016 by further strengthening its position in the Chinese market.. For its facility in Shijiazhuang (Hebei), which will produce 20 million /year of wall tiles, Lingshi has chosen LB''s Migratech technology for dry grinding and microgranulation of ceramic bodies.

lb dry grinding micro granulation. Welding Handbook Welding Smoke Scribd. The Welding Handbook. for maritime welders Maritime Welding Handbook Welding and Related Processes for Repair and Maintenance Onboard 11th edition Revision 0. Get Price; Ideadiez .

Continuous dry granulation has been an established process in the pharmaceutical industry for decades and is used for more than just moisture or temperaturesensitive products. Unlike classic wet granulation methods, this process does not require any energyintensive drying processes; this avoids the need for large investments in systems and production facilities, and lowers the costs per batch.

Dry granulation is typically used in the manufacture of tablets if the formulation ingredients are too fluffy or too susceptible to flowability problems for direct compression to be a viable processing option and/or too susceptible to degradation from heat and/or moisture for wet granulation to be a viable processing option for densification.

Lb Dry Grinding Micro Granulation. The unique feature of the production unit QbCon 174 is that the tablet production can be implemented either without granulation or with dry or wet granulation in one system Get Price Dry Milling and Dry Grinding Machineries LBTechnology LB Technology builds dry milling and dry grinding machineries for porcelain and ceramic tiles industry

We inform you that in order to improve your browsing experience on this website, LB Officine Meccaniche uses different types of cookies, including functionality cookies; advertising cookies; performance cookies that allow you to access your personal data while you are browsing.

Here, we demonstrate a new dry granulation method in which submicron particles can be granulatedinto monodisperse anddense 10mm particlesof specic shape and size at near yields with no waste. We call this method dry particle microgranulation (DPMG). Here, Liion battery spherical graphite, metal oxide cathode,

Dry Granulation: This process is used to form granules without using a liquid solution, because the product to be granulated may be sensitive to moisture and heat or does not compress well. Forming granules without moisture involves compacting and size reduction of the mix to produce a granular, free flowing blend of uniform size.

A dry preparation plant with Fusion granulation technology for porcelain tile production has been installed at Blizzard Vitrified in Morbi. LB maintains its market leadership in the dry grinding business in China. Lingshi, Guatemalan manufacturer signs agreement with Fioranobased company LB to expand its dry milling plant. 01/09/2015.

Lb Dry Grinding Micro Granulation . Lb Dry Grinding Micro Granulation Since 1973 lb spa designs and builds plants and machines for the ceramic industry and for the powders treatment in various industrial fields lb is world leader for the technological innovations dedicated to the processing of ceramic powders with innovative processes of weighing and batching dry colouring

MIGRATECH is the innovative system of dry grinding with microgranulation of ceramic designed by LB. Over the past 15 years, the company has perfectedthe technology of dry preparation of ceramic bodies, developing and optimizing system solutions targeted to different types of production,providing a very high quality of the finished product and a drastic reduction in []

WhatsApp)

WhatsApp)